Rapid industrial scale cooking of boiled ham using radio frequency electric fields

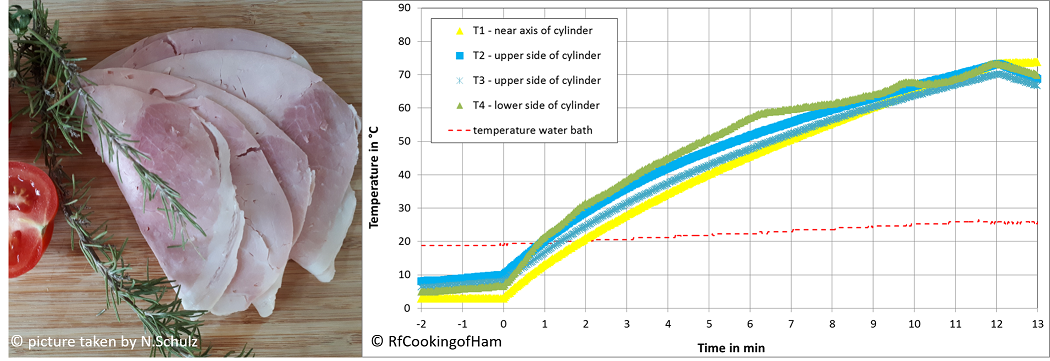

The project investigated the use of radio frequency (RF) electric fields to significantly reduce cooking times of cylindrical hams in plastic casings. The process uses a water bath filled with deionized water, in which the electric fields are applied to the food. The water as a high permittivity dielectric medium results in a very efficient transfer of electric fields into food items, in particular into salty ham with high electric conductivity. In cooperation with IRTA, cooking loss, casing meat adhesion, surface appearance and sensory attributes were assessed. RF-cooked hams showed a slightly lower cooking-loss, a smoother surface, were much easier to peel and were judged as slightly juicier and more gel-like than the conventionally cooked control samples.

Project consortium

Coordinated by

Fraunhofer Gesellschaft e.V. (DE)

Partners

Trumpf Hüttinger GmbH & Co. KG (DE); Danish Technological Institute - DMRI (DK); Instituto de Recerca i Tecnologia Agroalimentàries, IRTA (ES); Campofrio Food Group (ES)