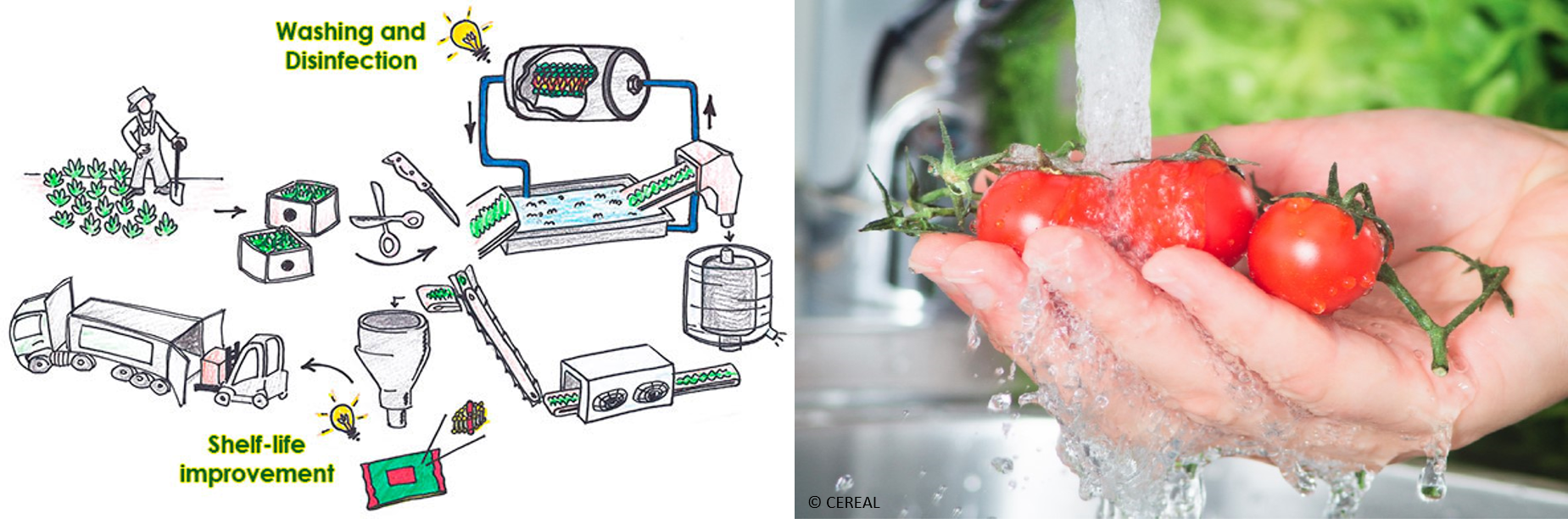

Improved and resource efficiency throughout the post-harvest chain of fresh-cut fruits and vegetables

The relevance of fruit and vegetables extends as they play a pivotal role in promoting consumers' health, thus reducing costs associated to obesity, cardio-vascular and other social diseases. Nevertheless, the introduction of new and safe ready-to-eat fresh products, particularly fruit and vegetable, requires significant improvements in produce cleaning. Proper disinfection technology is required to ensure microbial safety avoiding at the same time the formation of disinfection by-products such as chlorinated chemicals. Furthermore, the quality of fresh-cut products also depends critically on packaging technology, which has to preserve good appearance and flavour, as well as meet safety requirements.

In view to increase the capacity of the EU industry to provide safer and more durable produces the CEREAL project goals were; (1) the reduction of the inputs used in the processing of fresh-cut fruits and vegetables via the introduction of new membranes with biocidal functionality; (2) the increase of the shelf life of the packed fresh cut products by developing of a hybrid technology in which the use of ozone combined with ultrafiltration; (3) the accomplishment of a higher level of chemical and microbiological safety of processed produces via the production of new active packaging components for fresh produces, which are expected to increase shelf life and to reduce wastes.

Project consortium

Coordinated by

University of Almería (ES)

Partners

- Fraunhofer IVV (DE);

- RWTH Aachen University (DE);

- University of Alcala (ES); INIA (ES);

- Lappeenranta University of Technology (FI);

- Consiglio Nazionale delle Ricerche (IT);

- Luleå University of Technology (SE)